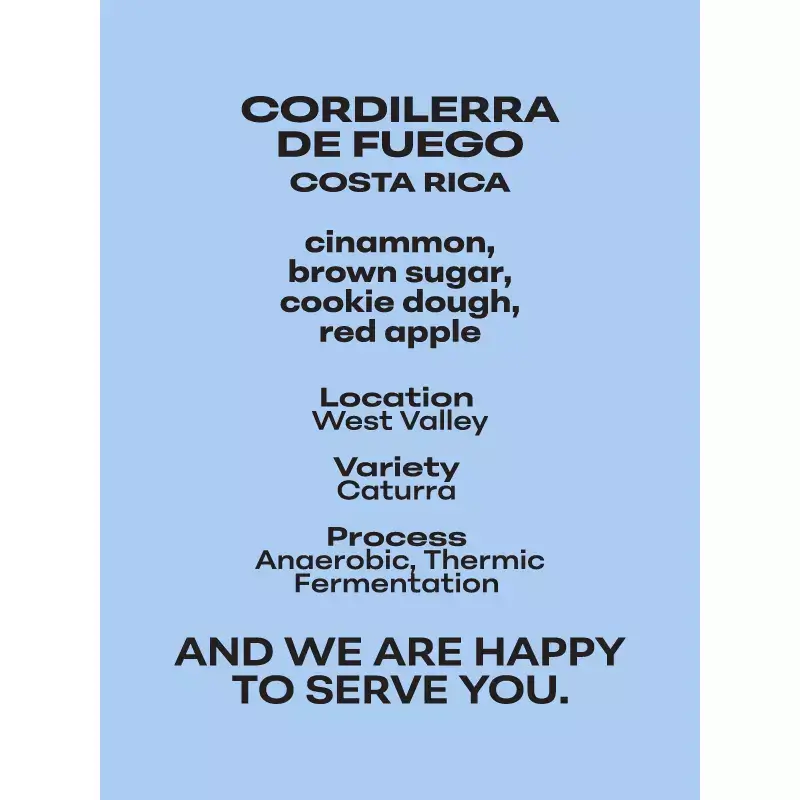

- Country

- Location

- Variety

- Process

- Roasting Profile

- Taste Profile

- Costa Rica

- West Valley

- Caturra

- Anaerobic Fermentation

- Omni (Roasted for Espresso & Filter)

- Cinnamon, Brown sugar, Cookie dough, Red apple

Coffee Profile

No Data Found

Coffee Profile

No Data Found

Region Information

Altitude: 1,600 - 1,750 M.A.S.L.

Farmer: Luis Eduardo Campos

Farm Size: 200 ha, 15 ha of coffee

Variety: Caturra

Harvest: November - March

Processing: Anaerobic fermentation, thermic fermentation

After graduating from university in 1984, Don Luis Eduardo Campos planted his coffee farm in Piedades del Sur, Alajuela. Don Luis has been constantly pursuing new and innovative ways to improve his coffee production. About ten years ago, he had the idea of an anaerobic fermentation with the objective of extracting the naturally occurring flavors of the coffee through a controlled fermentation process. After 6 years of research and tests, his anaerobic coffee was ready. The unique flavors and tasting notes of the anaerobic and thermic micro lots come from their special processing method. It all starts with handpicking very mature coffee cherries that have a Brix degree (a measurement of sugar content) near 26. Selecting the cherries when they are at their ripest allows them to have a high sugar content and thus feed both the anaerobic and thermic processes.

THE ANAEROBIC PROCESS: The coffee is de-pulped and put in stainless steel tanks with all its mucilage, which, in the absence of oxygen, purposely creates an anaerobic fermentation process. The process develops in a unique series of acids such as lactic and malic, translating to a very complex flavor. Once ready the coffee is 100% sun-dried.

FARMING PRACTICES: Don Luis is not only an innovative coffee processor, but he is also progressive in his farming practices. In 2017, he joined NAMA (Nationally Appropriate Mitigation Actions) whose objective is to dramatically reduce emissions of greenhouse gases within the coffee sector. The biggest project was the installation of solar panels, which supply 100% of the energy of the main office and 50% of the energy of the mill.